3D Printed Microfluidic Medical Devices: Rapid Prototyping Using LiveLink™ for MATLAB®

Recent advances in additive manufacturing enable rapid production of low-cost custom devices.[1-2] Despite modern 3D printers apparent resolutions on the order of tens of microns, for microfluidic applications there are challenges associated with the creation of channels below a few hundred microns,[3] including the removal of support materials. We present two case studies that use COMSOL Multiphysics® software with Livelink™ for MATLAB® to rapidly discover the boundaries of 3D printer capabilities and to guide the design of 3D printed devices.

First, we determine the minimum printable channel diameter for a 3D printer by using a MATLAB® script to rapidly create a test grid of many channels of varying sizes. This test grid is then exported as an STL file, which is sent directly to a PolyJet 3D printer. The printed test grid is evaluated to determine the limiting feature sizes that the printer can successfully print.

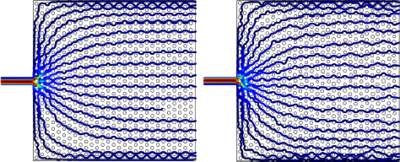

In the second example, we consider a micropillar array for cell sorting applications. In a similar manner to our first test, we 3D print the geometry file generated with our MATLAB® script and assess the quality of print. The pillar array is supposed to be symmetric and regular, but defects in printing may disrupt the symmetry. We use the Livelink™ for MATLAB® to generate a design with randomly perturbed pillar locations and investigate the resulting change in flow patterns with the fluid flow simulations and particle tracing. We compare the particle distribution in the symmetric and perturbed designs to determine the printing defect tolerance of our system.

We have used COMSOL Multiphysics® software and its Livelink™ for MATLAB® to design a test geometry for 3D printing, and have performed fluid flow and particle tracing simulations to investigate the effects of 3D printing defects on flow characteristics. Furthermore, the new model scripting capabilities introduced in COMSOL Multiphysics® 5.3 facilitate geometric manipulations to quickly iterate on 3D printed designs.

COMSOL Multiphysics® is a registered trademark of COMSOL AB.

MATLAB® is a registered trademark of The MathWorks, Inc.

下载

- spann_presentation.pdf - 2.34MB

- spann_abstract.pdf - 0.02MB