Characterization of Biochemical and Physical Parameters of a Skin Equivalent in a Two-Organ-Chip

Background and novelty

Organ-on-a-chip-systems represent a powerful alternative to substance testing in animal trials. The basic idea behind this approach is to emulate the smallest physiological unit of an organ on a chip. For this purpose, micro-environments must be created, that correspond to their natural space. The company TissUse has developed a two-organ-chip (2OC), which enables the cultivation of two tissues in one circuit (see Figure 1 a). Here the focus is laid on full-thickness skin equivalents (ftSE) cultivated in an 2OC [1] as a promising method for the dermal application in the field of pharmacy and cosmetics. For the dermal substance application, diffusion of the active ingredients plays a decisive role. Glucose consumption and lactate production are essential factors for evaluation of ftSE culture. COMSOL Multiphysics was used to simulate theses chemical and physical parameter in the 2OC in order to predict the substance distribution in the 2OC and to estimate the consumption of glucose and the production of lactate by the ftSE. Thus the effort of time-consuming tests can be reduced in advance.

Experimental approach

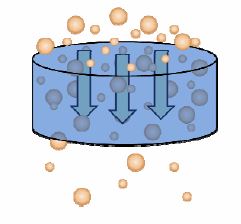

A method was established to determine experimentally the permeation of a fluorescent tagged substance [2] and glucose consumption as well lactate production of an ftSE in a 96 well cell culture insert system. The results of the experiments were integrated in COMSOL Multiphysics to simulate all the biochemical and physical parameter in a 2OC. For this purpose, the geometry of the 2OC was implemented in COMSOL with CAD import Module. The “Chemical Reaction Engineering” and the “Optimization” Module were used to simulate the diffusion process (see Figure 1 b). Furthermore, the “Chemical Reaction Engineering” Module was used to simulate the glucose consumption and the lactate production. CFD Module was additionally used to determine the substance distribution within the channel in the chip. For validation, the simulated values were compared to the experimental data.

Results

The experimental data could be described very well by the simulation (see an example on Figure 1 c). The simulation was used to calculate the substance diffusion and distribution in long-term experiments and to estimate when the glucose concentration becomes critical in the medium. These results will be presented.

References

[1] Schimek and Hsu et al., Bioengineering of a Full-Thickness Skin Equivalent in a 96-Well Insert Format for Substance Permeation Studies and Organ-On-A-Chip Applications (doi: 10.3390/bioengineering5020043) [2] Hsu et al., A Method for Determination and Simulation of Permeability and Diffusion in 3D Tissue Model in a Membrane Insert System for Multi-well Plates (doi: 10.3791/56412)

下载

- hsu_presentation.pdf - 0.74MB

- hsu_abstract.pdf - 0.02MB

- 7.jpg - 0.02MB