Development of a 10 kW Microwave Applicator for Thermal Cracking of Lignite Briquettes

Introduction:

The use of microwave energy for thermal cracking (from thermal stress and water pore pressure) of lignite-coal briquettes increases the lignite friability [1] and is beneficial for later chemical treatment inside a gasifier (for methanol production for example). An adequate use of microwave energy can improve the overall efficiency of the gasification process based on lignite coal briquetting [2, 3]. In this paper, a compact high power 10 kW microwave applicator operating at 2.45 GHz for fast volumetric heating and thermal cracking of lignite coal briquettes has been successfully designed, built and tested.

Use of COMSOL Multiphysics®:

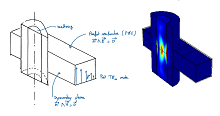

The applicator (Fig.1) is made of a high strength ceramic Silicon nitride tube (Si3N4) with 2.5 cm wall thickness crossing a rectangular channel made in a high strength aluminum bloc (Alumec 100) and can operate up to 65 bars with continuous feeding of briquettes. COMSOL Multiphysics® software was intensively used to improve the electromagnetic design and to compute the total stress in the critical parts of the applicator. A coupled electromagnetic, thermal and mechanical model was used in order to compute the von Mises stress in the ceramic cylinder and the aluminum block. The electrothermal model computes the power distribution inside the lignite material (Fig.2) and the temperature field inside the lignite material (with translation movement, continuous feeding), ceramic (Fig.3) and aluminum block. From the temperature field, the internal pressure and the pressure from the gaskets seals, it was possible with a linear elastic model including thermal expansion to compute the displacement and total stress field inside the ceramic (Fig.4) and aluminum block.

Results:

With an adequate cooling circuit, the temperature was relatively uniform (due to the high thermal conductivity of the aluminum bloc) with maximal temperature was about 40 / 50 deg C, and consequently, the thermal expansion and stress were limited. The COMSOL thermal fluid model was used to compute the temperature field inside the aluminum bloc for different flow rates. Experimentally, it was observed that the temperature of the bloc remains below 45 deg C during a run at 10 kW for about 20 min.

Conclusion:

In summary, the utilization of a ceramic silicon nitride tube is the key of this high pressure applicator because this material combines both a high mechanical strength and a very low dielectric loss factor. In operation, the aluminum bloc incorporating water channels remains below 45 deg C as predicted by thermal simulations. Overall, COMSOL was intensively used to perform sequential multiphysics simulations (electromagnetic, thermal, mechanical, fluid) in order to check the design of the applicator.

下载

- lepers_presentation.pdf - 14.63MB

- lepers_abstract.pdf - 1.64MB