Thermal Bridging Calculation of Three Steel Stud Wall Assemblies with Benchmarking

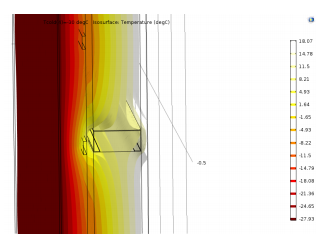

As a part of the Pan-Canadian framework for clean growth, Canada is intent on meeting its 2030 emission targets for which 17% of Canada’s total Green House Gas emissions come from buildings. Given this challenge, emphasis is being placed on developing building designs having greatly reduced energy use to the extent these can be regarded as net-zero ready. It is recognized that thermal bridges are areas of a wall assembly that have higher thermal transmittance than the surrounding wall components and hence create paths of greatly diminished thermal resistance. As a consequence, the effects arising from thermal bridging can significantly reduce the thermal performance of wall assemblies and thus can affect the overall thermal performance and total energy use in buildings. Such effects, as well, produce other undesirable risks such as the thermal discomfort of occupants and condensation in walls. In this project the Heat Transfer Module was used to model the total thermal performance of three steel stud wall assemblies from which the thermal bridging effects were calculated. Numerical simulations were completed on the wall assemblies in three dimensions. The modeling sequence for both series consisted of: (i) selecting and creating the geometry to be modelled; (ii) selecting the material properties; (iii) determining and applying the boundary conditions; (iv) performing mesh verification; (v) conducting the numerical simulations, and; (vi) comparing the results to those obtained from laboratory tests. Laboratory thermal tests were conducted on these wall assemblies in NRC’s Guarded Hot Box (GHB) following the test procedures given in ASTM C1363. The results from thermal tests were used to benchmark the results derived from simulation. The benchmarking procedure demonstrated that the techniques and procedures used to produce R and RSI values can accurately reproduce test measurements using measured (or typical) material properties and consistent boundary conditions. The 3-D geometries for the wall assemblies were created in Solidworks. The geometries were imported in the COMSOL Multiphysics® software and material properties were assigned to the corresponding domains. Temperature dependent thermal conductivities for the insulation materials were measured using a Guarded Hot Plate (GHP) in accordance with ASTM C519; these results were used in the simulations. Parametric sweeps of the thermal conductivities were conducted to capture the different boundary conditions to which the wall assemblies were exposed when subjected to different climate zones. The interior side of the wall assemblies was always exposed to 21 °C, whereas exterior wall temperatures of -5, -20 and -35 °C were used for the parametric sweep. Contact thermal resistances were in compliance with information provided in the 2009 ASHRAE Handbook-Fundamentals. Mesh verification was conducted on one of the wall assemblies to determine the effect of changes in mesh sizing. It was observed that the difference between the calculated R value and that measured was for Wall 1, on average, 4.34% which is below the ± 8% uncertainty reported for the NRC GHB. Average R-value differences of 1.42% and 4.80% were measured, respectively, for Wall 2 Wall 3.

下载

- ghobadi_presentation.pdf - 1.88MB

- ghobadi_paper.pdf - 1.1MB

- ghobadi_abstract.pdf - 0.05MB