了解多物理场仿真在基础研究和产品设计中的应用

各个行业的工程师和科研人员都在使用多物理场仿真来研发创新的产品设计和流程。他们在 COMSOL 用户年会上展示了丰富的技术论文和演示文稿,您可以从他们的研究成果中寻找灵感。

使用左侧【快速搜索】工具查找您感兴趣的研究,或按照应用领域进行筛选。

查看 COMSOL 用户年会 2020 论文

Simulation of Neurotransmitter Sensing by Cyclic Voltammetry under Mechanical Motion of a Neural Electrode

Neural electrodes for sensing neurotransmitters are embedded within the brain, detecting electrical signals ... 扩展阅读

A Phase Field Model for Lithium Ion Battery Particles

In this study, a three-dimensional (3-D) phase field model was developed to better understand the parameters ... 扩展阅读

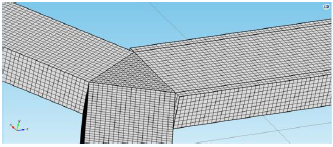

Effect of Mass Flow Induced by a Reciprocating Paddle on Electroplating

The reciprocating paddle electrochemical plating cells have been widely applied in microelectronics industry ... 扩展阅读

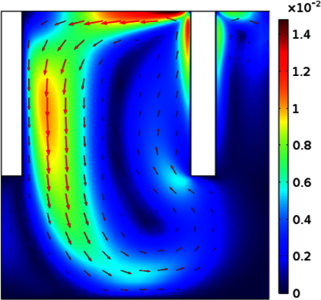

MHD Electrolyte Flow within an Inter-electrode Gap Driven by a Sinusoidal Electric Field and Constant Magnetic Field

PECM is a necessary extension to traditional ECM for some high-performance materials. Electrolyte flow in ... 扩展阅读

The Effect of Fuel and Oxidant Pumping on the Performance of a Membraneless Microfluidic Fuel Cell

For the commercialization of membraneless microfluidic fuel cell, voltage and minimum power demand for ... 扩展阅读

Accelerated Electrochemical Machining Tool Design

Electrochemical machining (ECM) is a manufacturing technology that allows metal to be precisely removed by ... 扩展阅读

Modeling the Influence of Differential Aeration in Underground Corrosion

A finite element model for underground corrosion is presented. The model is capable of predicting regions ... 扩展阅读

Electrical and Bubbly Flow Modeling of a Molten Salt Electrolysis Cell

A laboratory-scale electrolysis cell for the recovery of metals is simulated with COMSOL Multiphysics® ... 扩展阅读

Visualisation of the Internal Processes of a Fuel Cell with the Help of an Application Built with the COMSOL Multiphysics® Software

The objective was to make a visualisation application for the pupil's lab of the University of Applied ... 扩展阅读

Lithium Ion Battery Thermal Safety and Prevention Measures

Lithium ion battery safety problem has attracted the whole world’s attention essentially after the explosion ... 扩展阅读