Simulating Approaches for Heating Process in Continuous Furnaces

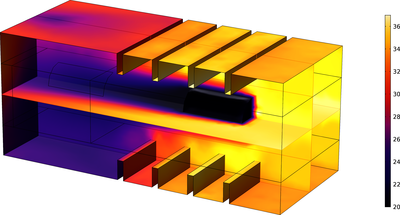

Heating of pieces evolving in tunnel furnaces is an argument of high interest in several industrial processes such as thermal treatment of metals, glass production and food industry.Because of pieces move into the furnace, heat flux they receive from fixed heat sources is variable in time. Moreover, if the heating tunnelhas functional or geometrical differences from one of its portion to another, in a chosen time step, pieces located atdifferent position receive different time-variable heat fluxes. This paper presents some modelling strategies adopted in order to simulate the heating process in this kind of applications. Different models are presented to simulate the heating process, depending on: i) pieces move continuously or step-by-step along the furnace; ii) furnace has uniformly distributed heat sources or not; The easiest method we considered consists in a transient simulation of one piece considered at fixed position: it well approximates the process when pieces evolve step-by-step in furnaces having heat sources uniformly distributed along the piece’s path. Otherwise, the most complex method is based on computational domainsdeformation. In this case, a moving mapped mesh is built to “follow” pieces displacement by stretching / compressing the grid elements (Fig. 1). This approach well fits with industrial applications where pieces linearly and continuously move in a chamber where heat conditions depend by piece’s position.

下载

- petrone_poster.pdf - 1.14MB

- petrone_abstract.pdf - 0.15MB