Advanced modelling for Li-ion battery design, diagnostics and R&D

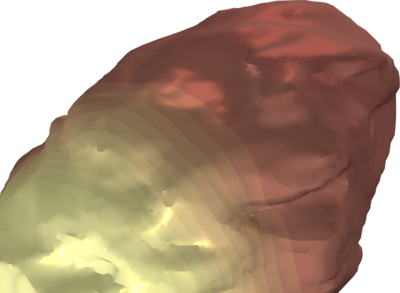

Lithium-ion batteries are leading the electrification transition, particularly within the transport sector. However, numerous challenges still remain, with fast charging emerging as a major concern. To speed up research, physics-based models are frequently employed alongside experimental investigations. These models rely on various parameters that must be accurately estimated or fitted to experimental data. Moreover, predicting cell behaviour during intense operation conditions requires the incorporation of advanced physics and degradation phenomena while, at the manufacturing level, tracing the impact of the uncertainty of critical design parameters on performance is crucial to minimise off-spec batteries. All these challenges are addressed here with COMSOL Multiphysics®. Among many factors, Pseudo-2-Dimensional (P2D) Li-ion battery models rely on critical parameters like the solid-state Li diffusivity in active materials and intercalation kinetic constants. We applied the Optimization Module to carry out this task by using Galvanostatic Intermittent Titration Technique (GITT) experiments, performed in diffusion regime, to fit the Li diffusivity as a function of state of lithiation; then, charge/discharge voltage curves at various C-rates are used to calibrate the kinetic constant in a disordered carbon half-cell (Ahn et al., 2023). The analysis shows that a single-particle model (SPM) is insufficient to reproduce the voltage relaxation in GITT and underestimates Li diffusivity, so that the particle size distribution of the active material must be considered in a multi-particle model (MPM) for a more robust estimation of kinetic and transport properties (Figure 1). When the battery is operated in fast charging conditions, phenomena such as graphite phase separation (i.e., staging) and lithium plating need to be considered in the model. We integrated a phase-field approach, rooted on non-equilibrium thermodynamics (Bazant, 2013; Lagnoni et al., 2024), within the P2D modelling framework and extended it also to 3D microstructure-resolved models (Lu et al., 2023). The fourth-order partial differential equation in Li concentration of the phase-field model is conveniently implemented as two second-order equations by using the General Form PDE interface of the Mathematics Module, thus simulating phase separation in graphite (Figure 2a). This is then coupled with in-house kinetic expressions of lithium plating/stripping, calibrated with operando optical experiments (Lu et al., 2023), which predict the distribution and thickness of Li plating within 3D microstructures (Figure 2b,c). Finally, at the manufacturing level, the uncertainties of critical design parameters (i.e., electrode thickness, porosity, particle radius) need to be considered to trace their impact on battery performance and minimise off-spec batteries. The Uncertainty Quantification Module is used to build a surrogate model from P2D model simulations and thus track, in a Monte Carlo simulation, how production tolerances affect the fraction of off-spec batteries with respect to the accessible capacities at different charge/discharge times used as key performance indicators (Figure 3). In summary, by combining multipurpose modules and in-house implementations, COMSOL Multiphysics® enables for advanced modelling of Li-ion batteries accounting for particle size distributions, degradation phenomena, and production tolerances, thus enabling a physics-based insight to inform fast-charging protocols.

下载

- bertei_9351_poster.pdf - 0.66MB

- 1_marco_lagnoni.pdf - 1.79MB