Chemical Mixing and Washing in Fluidic Diagnostic Systems

Recent events underscore the importance of rapid diagnostic tests for detecting viruses such as the SARS-CoV-2 coronavirus or for screening cancer biomarkers. Many fluidic-based diagnostics applications require careful control of chemical and biological species concentrations. In this talk, we discuss two such examples: mixing in a microwell and chemical carryover in a microchannel.

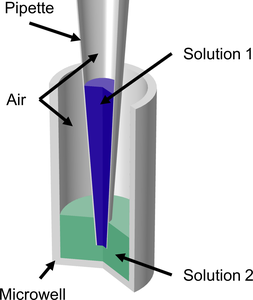

In the first example shown in Figure 1, two solutions are mixed in a microwell by repeatedly dispensing and withdrawing solution from a pipette. COMSOL Multiphysics® is used to model the number of cycles required to achieve a desired level of mixing. Figure 2 shows the flow field and concentration profile at different times as solution is dispensed and withdrawn. We compare and contrast the results when using a fast pipetting cycle which withdraws and dispenses small volumes of liquid versus a slower cycle which displaces large volumes.

Removing reagents or sample from a previous processing step via a wash cycle is a common challenge in diagnostic assays (Figure 3). In this example, COMSOL Multiphysics® simulations are used to predict and optimize wash cycle performance. Simulations indicate regions with where reagent remains, and how that depends on total wash time and solution volume. In Figure 3, the same wash volume (blue) flows through the channel. Increasing the wash solution velocity leads to a trade-off where the total wash time may be reduced, but a higher wash volume is required to successfully remove the reagent from recirculation zones in the corner.

COMSOL Multiphysics® is a powerful tool to help understand, design, and optimize mixing and wash cycles and to assess trade-offs and design decisions. We can use simulations to quickly test and optimize device geometries, parameters, and operation protocols before prototyping, thereby reducing costs and saving time.

下载

- Spann COMSOL Conference 2020.pdf - 1.76MB