Hot Cracking in Nb-Si Alloys

Introduction With the vast development in the aerospace industry it is inevitable that currently used materials such as Nickel based super alloys will soon reach its peak performance. Hence developing alternative materials with similar properties that could be enhanced further is crucial. With the focus turned in to NB-Si alloys as a future replacement, this study will look in to Solidification cracking that occur during the additive manufacturing process.

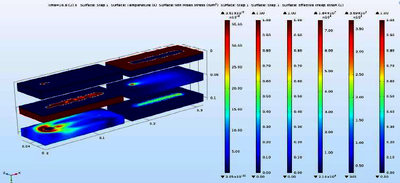

COMSOL setup A 3D block was used as the geometry. Material properties in the model were manually evaluated and added as functions allowing to change the alloy composition as needed. Heat Transfer in Solids interface was used to add a heat source. The heat source was modelled using the Goldak double Ellipsoid model. The Solid Mechanics interface was added to the model to evaluate the stresses along with thermal expansion and creep models. The Creep option was set using the Norton creep model and thermal expansion model was added using the secant coefficient of thermal expansion model. The domain ODEs and DAEs physics interfaces were used to add variables fL(fraction of liquid), fS(fraction of solid) and fP(fraction of powder), in order to simulate phase change. A time dependent study was carried out in order to analyse stresses and creep strain during phase change.

Expected The alloy susceptibility to hot cracking is expected to be proportional to the rate of solidification.

下载

- fernando_poster.pdf - 0.68MB

- fernando_abstract.pdf - 0.2MB