Modeling and Analysis of Droplet Behavior in Mist-CVD for Ga₂O₃ Thin Film Deposition

Mist chemical vapor deposition (mist-CVD) has recently attracted interest as a facile, cost-effective, and environmentally friendly method for depositing thin films of various materials. In this method, mist droplets containing the reactant solution are injected into the reactor and transported by a carrier gas toward the substrate. The substrate is positioned in a high-temperature zone of the reactor, where droplet evaporation occurs. During evaporation in the high-temperature zone, the reactants are released from the droplets and diffuse toward the substrate, where they contribute to the formation of a thin layer.

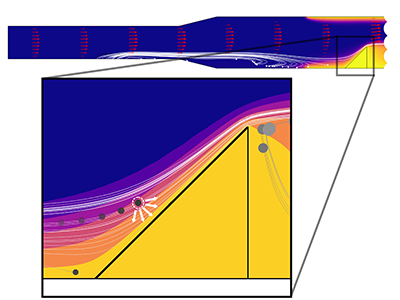

We have developed an in-house mist-CVD reactor for the deposition of thin films of Ga2O3. To simulate the temperature, pressure, and velocity distributions within the reactor, we modeled our system in COMSOL Multiphysics® software using the CFD module, where 2D model of the reactor tube with droplet and carrier gas inlets and single outlet was implemented. We also employed the particle tracing module to track droplet trajectories and to monitor their evaporation.

Initially, detailed flow and temperature fields were analyzed for different inflow velocities and compared with experimentally obtained data for different inlet flow velocities. Then, droplets were introduced to the system, and the time and location of complete droplet evaporation were investigated. This is crucial, as successful thin film deposition requires the carrier gas flow velocity in the mist-CVD reactor to be optimized such that the droplet does not fully evaporate (and form a solid particle) before reaching the area above the substrate. Additionally, we analyzed the residence time of droplets in the temperature boundary layer above the substrate, as well as the amount of reactant gas released through droplet evaporation, using LiveLink™ for MATLAB®. The results were then compared with experimentally determined thin film thicknesses measured by secondary electron microscopy.

Modeling droplet behavior in the mist-CVD reactor is essential for a fundamental understanding of the phenomena occurring within the reactor body. These insights are valuable not only for establishing optimal growth conditions to fabricate defect-free thin films with tailored morphological properties, but also for advancing the development of the mist-CVD reactor as a functional device.