Multiphysics Modeling of Photo-Polymerization in Stereolithography Printing Process and Validation

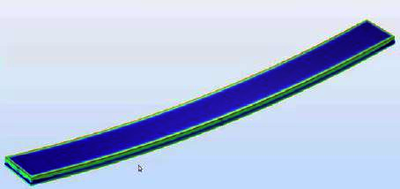

The free-radical photo-polymerization of thermoset polymers is an essential part in additive manufacturing, in particular for the Stereolithography (SLA) printing technique. A better understanding of the photo-polymerization and its relation to the process is required to improve the quality of the products, namely minimizing the resulting warpage after printing and strengthening its mechanical properties. Therefore, in this paper, a workflow including a multiphysics model and material characterization methods is developed to investigate the influence of the photo-polymerization on the printed part during the SLA process. As shown in the Figure, the multiphysics model is implemented in COMSOL Multiphysics© and it involves a chemical reaction and a thermomechanical deformation during the photo-polymerization process. For the chemical reaction, it focuses on solving an ordinary differential equation (ODE) of the double-bond conversion and a partial differential equation (PDE) of the light propagation in the material. The thermomechanical problem is solved by combination of the Structural Mechanics and Heat Transfer modules. Moreover, the simulation is operated by LiveLink™ for MATLAB® to achieve control over the layer-by-layer additive manufacturing process. On the other hand, the kinetics parameters of the material are characterized by an in-situ measurement of the double-bond conversion. The shear storage modulus is correlated to the double-bond conversion by monitoring the oscillation test in a UV-rheometer. In the end, the final double-bond conversion and the warpage of rectangle beams printed in a commercial 3D printer are compared with the prediction of the developed model. The comparison indicates that the residual stress developed throughout the printing process may dominate the final deformation of the printed product.

下载

- gao_presentation.pdf - 1.11MB

- gao_paper.pdf - 0.67MB

- gao_abstract.pdf - 0.02MB