Simulating the Influence of the Nozzle Diameter on the Shape of Micro Geometries Generated with Jet Electrochemical Machining

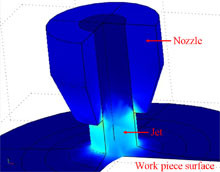

Jet Electrochemical Machining (Jet-ECM) is an unconventional procedure for micromachining. Based on localized anodic dissolution three-dimensional geometries and microstructured surfaces can be manufactured using Jet-ECM. COMSOL Multiphysics is used at Chemnitz UT to simulate the electric current density in the jet and the dissolution process. A mesh displacement dependent on the normal current density implements Faraday's law in the model to simulate the profile shape. In this study the influence of the nozzle diameter is investigated. The results demonstrate that the simulated diameter of Jet-ECM point erosion is a linear function of the nozzle diameter. The function can respectively be used for interpolation and extrapolation of the Jet-ECM erosion width. The comparison of simulated and measured point erosion profiles demonstrate a good coincidence.

下载

- Hackert.pdf - 0.18MB