Simulation of an Ethane Steam Cracking Reactor for Ethane-Propane Mixtures

This study allows to establish the possibility to carry out the pyrolysis of mixtures of ethane-propane in an existing steam-cracking reactor (SCR) originally designed for ethane pyrolysis. The final goal of this study was to minimize new investments, e.g. a purchase of new equipment, reactor modifications or change of burners. Based on molecular kinetic models proposed by Froment et al, a COMSOL Multiphysics® simulation was developed; first, the ethane pyrolysis simulation was developed and then it was validated using SCR data from an actual Ethylene Plant (ECOPETROL, Colombia). The coke accumulation phenomenon and its effects on the operating time were also considered. Normal plant operating conditions were defined by analyzing a whole number of eighteen work cycles (930 days), which were used to validate the pyrolysis simulation of propane and their mixtures. Once the ethane model was validated, the pyrolysis kinetics of pure propane and ethane-propane was then incorporated. These simulations were performed using the specifications of the original mechanical design of ethane SCR.

The SCR was simulated as a plug flow reactor. Initially, the OD stationary model was chosen in COMSOL Multiphysics® using the reactor volume as an independent variable. The Chemical Reaction Engineering module was used to introduce the chemical species and the definition of reaction kinetics. Variations of concentration, temperature and pressure were included. The thermodynamics properties were calculated using an external module. Afterward, a simplified 2D stationary model was developed with a known heat density flow. The hydrodynamics was not included in the 2D model due to the expensive computer work. The work performed in this study allowed to identify that the utilization of a current low feed temperature of SCR causes a negative impact on the ethane conversion to ethylene, with a potential profit margin of 7 million dollars annually.

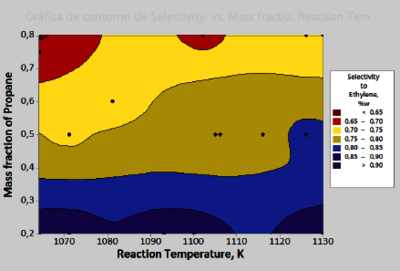

Finally, a fractional factor analysis with two levels and three factors was performed to study the interactions of the main operating variables with the selectivity to ethylene. The results indicate that it is possible to carry out the propane pyrolysis or their mixtures in the SCR without mechanical changes, providing that the pyrolysis could be carried out under the recommended operating conditions. In the future, an interface will be developed to allow that the operators and plant engineers utilize daily the developed models for allowing a better assessment of the operation and giving support for the decision-policies, which ultimately result in greater benefit for the ethylene production.

下载

- martinez rey_presentation.pdf - 1.61MB

- martinez rey_poster.pdf - 0.49MB

- martinez rey_abstract.pdf - 0.02MB