Simulation of Laser-Induced Forward Transfer of High-Viscosity pastes

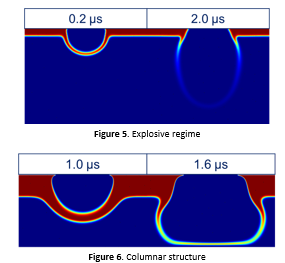

Laser-Induced Forward Transfer (LIFT) is a direct-write technique for transferring small volumes (even picolitres) of material through laser irradiation. The characteristics of this material can be in a wide range of viscosities and can respond to different rheological behaviors, from solid matter to low-viscosity fluids. Its resolution is about a few micrometers, so complex patterns can be printed using optical control of the laser. The LIFT simplest setup comprises a transparent substrate with the transference material deposited as a thin layer onto it. Through the laser irradiation, a small amount of material is vaporized, so the pulse energy is transformed into kinetic energy. To prevent the material from being harmed by the laser pulse, a deformable intermediate layer can be set between the substrate and the material. This variation was coined as Blister-Actuated LIFT (BA-LIFT) for its use with mainly biological material. The fluid dynamics are strongly dependent on the physical and geometrical properties of the material layer, the distance between the acceptor and the donor substrates, and the laser pulse parameters for both techniques. LIFT of high-viscosity pastes has been used as an alternative of screen printing in photovoltaics, despite the extreme properties of these materials. When the LIFT transference is done under the formation of a stable column between the donor and the acceptor substrates, the separation movement of both substrates affects the shape of the final transferred voxel. In this work, two models are presented built upon the Laminar Two-Phase Flow, Phase Field physics interface: for BA-LIFT, the motion is induced through a moving wall that resembles the movement of the intermediate layer. LIFT process model has been simplified including a flow inlet node that simulates the expansion and pressurization of the vaporized material. For their validation, image series have been acquired using an ultrafast image system. Even more, the modification of the dynamics in BA-LIFT model allows reproducing some secondary effects (such as bulgy shapes and secondary jets) that have been observed after several μs in low-viscosity fluids (glycerol/water mixtures in this work). The main goal of this work is to reproduce the different regimes observed in both processes: non-transference, single jet, and bulgy shapes for BA-LIFT; non-transference, explosive, cluster, dot, and column transference for high-viscosity LIFT of metallic pastes. The implementation of a moving-wall acceptor substrate in LIFT model allows understanding the influence of the separation step in the final shape of the transferred material.