划痕镀锌钢样品的加速腐蚀试验

Application ID: 130341

一种用于测试材料大气腐蚀抗力的既定基准方法是在气候试验箱中进行加速腐蚀试验 (ACT),主要目的是可靠且快速地预测材料的长期特性。ACT 试验通过几周的时间对样品施加循环条件,典型的加速腐蚀的测试内容包括:升高的温度、反复的干湿循环以及添加盐分。样品可以具有各种形状和尺寸,适用于研究缝隙腐蚀、电偶腐蚀或样品受损后的腐蚀行为。

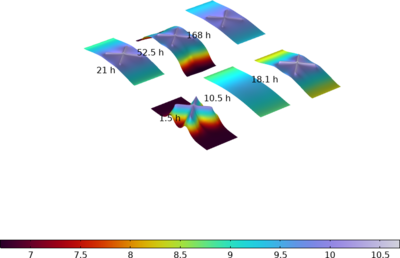

本例研究了一个带有交叉划痕的镀锌钢样品,这些划痕完全穿透了锌涂层,并露出基底钢材。模拟的腐蚀过程基于一项为期 7 天的虚拟 ACT,求解了覆盖样品表面的薄液膜,并展示了局部 pH 值变化、腐蚀产物以及涂层劣化的情况。

案例中展示的此类问题通常可通过以下产品建模:

您可能需要以下相关模块才能创建并运行这个模型,包括:

- COMSOL Multiphysics® 和

- 以下模块之一: 电池模块, 腐蚀模块, 电化学模块, 电镀模块, 或 燃料电池和电解槽模块

建模所需的 COMSOL® 产品组合取决于多种因素,包括边界条件、材料属性、物理场接口及零件库,等等。不同模块可能具有相同的特定功能,详情可以查阅技术规格表,推荐您通过免费的试用许可证来确定满足您的建模需求的正确产品组合。如有任何疑问,欢迎咨询 COMSOL 销售和技术支持团队,我们会为您提供满意的答复。