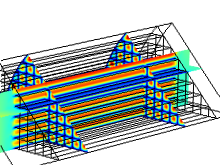

3D Simulation of an Ethanol Reformer

In order to improve hydrogen production in an ethanol reformer it is needed to understand what happens inside it. Also, a simulated model can simulate different work conditions avoiding the necessity of doing tons of experiments.

A 3D computational fluid dynamics simulation study of ethanol steam reforming (ESR) in a plug flow microreactor has been carried out. A kinetic model describing the ESR over a RhPd/CeO2 catalyst has been established and implemented. The model includes the ethanol decomposition into hydrogen, methane and carbon monoxide, the water gas shift (WGS) reaction, and the reforming of methane (MSR) to carbon monoxide or carbon dioxide. A 20 mm diameter tubular reactor filled with a cordierite honeycomb containing square channels of 0.9 mm width (400 cpsi) has been used.

For solving the problem four different COMSOL Multiphysics® interfaces have been used. First, Chemistry interface has been chosen to calculate the kinetics and thermodynamics of all the reactions. Second, the Heat Transfer in Fluids interface has been chosen to calculate heat and temperature variations on the fluid, since there are exothermic, endothermic reactions and an exterior heat source. Third, to simulate the transport of species the Transport of Concentrated Species has been selected, choosing simplified Maxwell-Stephan equations (mixture-averaged) to simulate the diffusion phenomena. Finally, the Creeping Flow (CF) is used to solve the fluid flow with Navier-Stokes equations.

The results obtained were contrasted with the experimental results taken from E. López, J. Llorca, N. J. Divins, A. Anzola, S. Schbib, D. Borio, “Ethanol Steam Reforming for Hydrogen Generation over Structured Analysis”, International Journal of Hydrogen Energy 38 (2013): 4418-4428.

The COMSOL Multiphysics® model can reproduce accurately the experimental results in the range 3-6 bar pressure and from 500 K to 950 K.

下载

- cifuentes lópez_poster.pdf - 0.51MB

- cifuentes lópez_abstract.pdf - 0.04MB