Electrothermal Study of Cu-CNT Composite TSV Using COMSOL Multiphysics®

Modelling 3D IC structures with Through Silicon Vias (TSVs) and micro bumps is a promising technique to achieve “more than Moore” integration. Conventionally, Copper (Cu) is used as a TSV material. However, due to rapid scaling of interconnect, problems like electro-migration and surface roughness scattering become prominent. Carbon nanomaterials are an emerging solution due to its properties like high thermal conductivity and better ampacity. Carbon Nanotube (CNT) as TSV and Graphene Nanoribbon (GNR) as interconnect are considered to improve the performance of 3D ICs. However, if a Cu-CNT composite is used as a TSV material, it will not just enhance the reliability than copper, but will also improve the electrical conductivity than CNTs. Furthermore, TSVs also provide a solution to problems like heat crowding and hotspots generated in the 3D IC structure. This paper, for the first time provides a comparison of the electro-thermal behaviour of Copper, CNT and Cu-CNT composite and also takes into account its anisotropic property to choose between, as a TSV material.

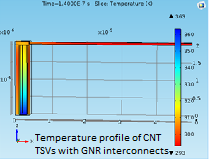

In this work the static and transient electrothermal behaviour of interconnect and TSV structure has been analysed using COMSOL Multiphysics®. A heat transfer model in Solid Mechanics interface coupled with Electric Currents interface is used to calculate the temperature variations along the entire structure. The dynamic behaviour of temperature in copper, Cu-CNT composite and CNT is compared. The electrical conductivity of these three materials is also analysed. We can draw conclusions that Cu-CNT composite provides better thermal capabilities compared to copper and better electrical conductivity if compared to CNTs.

下载

- Komal_Sable.pdf - 0.7MB

- Komal_Sable.pdf - 0.7MB