Numerical Analysis Of Entry Length In Cleaning Test Rig

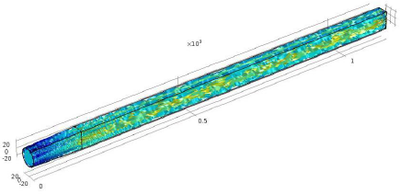

Fouling and cleaning processes present a major impact to the manufacturing industry in terms of economics, product quality, product safety, and plant efficiency. An efficient cleaning process is essential is order to remove fouling to maintain quality and safety of production process as well as the product. Thus, cleaning should be done with minimum cost and time, and understanding soil properties and how cleaning happened, will help in achieving the industrial goal of minimizing its costs. This study aims to investigate how forces in a hydrodynamic systems can promote/enhanced cleaning process of fat-based food fouling. An upgrade to an existing cleaning rig at the Universiti Putra Malaysia, consist of a rectangular flow channel with a test section to monitor the cleaning process was conceptually designed for this purpose. The use of computational fluid dynamic (CFD) has enabled more flexibility in the design process and similar to Sargison et al (2009), allowed a series of different design scenarios to be tested to finalize the conceptual design of the channel. The COMSOL Multiphysics software was used to test the proposed channel designs: one without settler and another with settler in the rectangular channel assembly. Our main objectives are to visualize fluid flow pattern in the channel and to predict the best entry length, Le where flow is fully-developed in order to decide appropriate location of the test section in the assembly.

下载

- nordin_poster.pdf - 1.44MB

- nordin_abstract.pdf - 0.52MB