Towards a Data-Driven Framework for Predictive Electrochemistry in Solid Oxide Cells

The transition to a hydrogen-based, renewable energy economy demands scalable and highly efficient electrolysis technologies. Solid Oxide Electrolysis Cells (SOECs) offer a particularly promising path, outperforming other electrolysis technologies in terms of efficiency and thus promising hydrogen generation at competitive or even lower costs [1,2]. However, widespread technological implementation of SOECs remains constrained by challenges in materials development, especially concerning long-term stability and degradation resistance under operational conditions. Traditionally, material development has relied on time-consuming, costly, empirical approaches involving iterative synthesis and experimental testing. More recently, artificial intelligence (AI) has emerged as a tool to identify promising material candidates more efficiently. However, these systems depend on large, high-quality datasets, which are typically expensive and labor-intensive to generate experimentally. Here, physics-based modeling provides a valuable opportunity to supplement and enhance these datasets, helping to accelerate material research.

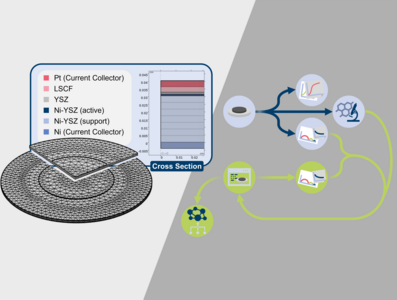

To address these challenges, we are developing a multiphysics-based finite element model [3-6] designed to serve as the core of a data-driven framework for SOEC material research (Figure 1). The model aims to leverage detailed material data with a particular focus on the microstructure to simulate and predict electrochemical performance. The latter, therefore, can be used as the target variable that should be optimized within the broader framework. By integrating real-world microstructural parameters [6] obtained from focused ion beam–scanning electron microscopy (FIB-SEM) analyses and validating the simulations against experimental electrochemical performance data, the model can be iteratively refined and continuously improved. This approach not only enhances predictive accuracy but also provides us with valuable insights into underlying degradation mechanisms and performance-limiting processes. Developing a fundamental, in-depth understanding of these microstructural effects is essential for improving durability and enabling the commercial scalability of SOEC technology.

The model is implemented in COMSOL Multiphysics® to allow easy coupling of multiple physical domains. While the initial model version is based on only using the predefined water electrolysis physics interface, efforts are underway to implement the Free and Porous Media Flow module for improved modeling of diffusion phenomena. Using COMSOL’s multiphysics environment also opens pathways for future extensions, such as simulating CO₂ and co-electrolysis via the chemistry module.

During model development, an extensive benchmarking process, including rigorous mesh independence studies and geometry variations, was conducted via calculating current–voltage (i–V) curves to ensure high numerical accuracy and stability while balancing computational cost. After successfully completing these benchmarks, the model demonstrated robustness across a broad parameter space. Initial comparisons with experimental data, however, revealed deviations that are attributed to simplified treatments of diffusion phenomena in the current model. To address this, further refinements using COMSOL Multiphysics’ Free and Porous Media Flow module are already underway. Moreover, preliminary assessments of key material and electrochemical parameters have shown the model’s ability to capture expected trends within the range of currently implemented processes, indicating that the model is on a promising path towards modeling real-world systems. In addition, impedance spectroscopy simulations are currently being implemented to provide further insight into frequency-dependent effects and to help dissect the contributions of individual physical processes to the overall cell behavior.