了解多物理场仿真在基础研究和产品设计中的应用

各个行业的工程师和科研人员都在使用多物理场仿真来研发创新的产品设计和流程。他们在 COMSOL 用户年会上展示了丰富的技术论文和演示文稿,您可以从他们的研究成果中寻找灵感。

使用左侧【快速搜索】工具查找您感兴趣的研究,或按照应用领域进行筛选。

查看 COMSOL 用户年会 2025 论文

Concerning the reduction of fossil-energy use from industrial processes, power generation and transportation, ... 扩展阅读

Hydrogen has great potential to be the fuel of the future through utilization in fuel cells, but it is rarely ... 扩展阅读

This study investigates the effect of uniform magnetic field on the deformation of a ferrofluid droplet in a ... 扩展阅读

Viscoelastic flow of polymer based energetic materials exiting an extrusion die is a particularly challenging ... 扩展阅读

Optimization of mixing in microfluidic devices is a popular application of computational fluid dynamics ... 扩展阅读

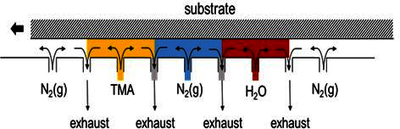

Atomic layer deposition(ALD) is one proven method to deposit ultra-thin films. ALD is advantageous for its ... 扩展阅读

At the Kansas City National Security Campus (KCNSC), simulation analysts are often called upon to evaluate ... 扩展阅读

Passive, one-way valves, also known as check valves, while common at the macro scale, are an essential ... 扩展阅读

The field of Biomedical Engineering is expanding at an exponential rate. As we began to unravel clues about ... 扩展阅读

Hydrodynamics of fixed bed reactors involve complex interactions of gas and liquid phases with packed solids. ... 扩展阅读