了解多物理场仿真在基础研究和产品设计中的应用

各个行业的工程师和科研人员都在使用多物理场仿真来研发创新的产品设计和流程。他们在 COMSOL 用户年会上展示了丰富的技术论文和演示文稿,您可以从他们的研究成果中寻找灵感。

使用左侧【快速搜索】工具查找您感兴趣的研究,或按照应用领域进行筛选。

查看 COMSOL 用户年会 2025 论文

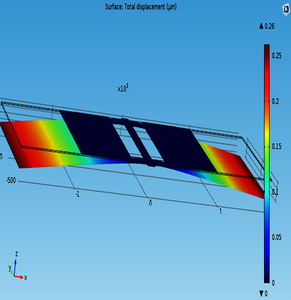

At the micron-level, thermal actuation exerts larger forces compared to the widely-used electrostatic ... 扩展阅读

The hearing impairment is affecting more than 360 million people all over the world.In India alone, 63 ... 扩展阅读

A Piezoelectric Directional Microphone is demonstrated based on a bio-mimetic design inspired by the ... 扩展阅读

Modern aluminum casement windows consist of an inner and outer profile made of aluminum, which are separated ... 扩展阅读

Due to the advantages of induction heating as a method for precise and efficient local heating, it is ... 扩展阅读

An extension of the Solid Mechanics interface in COMSOL Multiphysics® is presented to analyze localized ... 扩展阅读

Mechanical product design is crucial in many engineering field and lots of industries. CAE simulation has ... 扩展阅读

Crack detection is and has been an active field of exploration, both theoretical and applied for a number of ... 扩展阅读

Encouraging students to take on a Science, Technology, Engineering, and Math (STEM) major has recently been a ... 扩展阅读

Thermoelectric materials have no theoretical limit to conversion efficiency of heat into electrical power. In ... 扩展阅读