How to build a Digital Twin COMSOL based App for industrial continuous monitoring

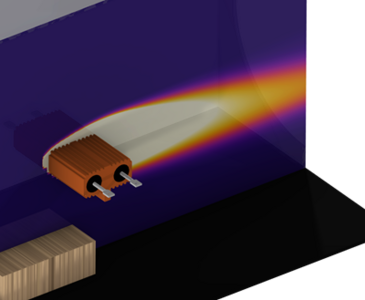

In the context of numerical simulation with COMSOL Multiphysics, the implementation of digital twin models for continuous monitoring represents one of the most promising frontiers for improving diagnostics, efficiency and process control in complex systems. In particular, digital twins enable real-time estimation of physical quantities that are difficult to measure directly or are inaccessible using conventional sensors. The main advantage of this approach lies in the speed at which reliable results can be obtained, by integrating simulation, real-world data, and artificial intelligence into a unified workflow. The proposed models and methods are based on the training of a deep neural network (DNN) within the COMSOL environment, using the dedicated nodes available in the Model Builder. The physical model is simulated under a range of varying boundary conditions to generate the dataset for training. Once the neural network is defined and trained, its outputs undergo a postprocessing phase to optimize the predicted values and to design interactive user interfaces for real-time visualization. The workflow also includes automated management of input variables through CSV files continuously updated by field sensors. The synchronized reading of this data is made possible by COMSOL’s Time Events node, which allows for dynamic updating of boundary conditions—thus simulating the real-time behavior of the monitored system. The integration of these tools enables the creation of efficient, adaptive digital twins that are immediately usable even in complex industrial environments. The results obtained show that integrating a deep neural network into the physical model allows for accurate predictions in significantly reduced time compared to full numerical simulations, while maintaining a high degree of consistency with the original physics-based model. The procedure has been validated on realistic case studies, demonstrating the digital twin’s ability to respond in real time to changes in operating conditions and to provide strategic insights even in the absence of direct sensors. Moreover, managing the entire process within the COMSOL environment drastically reduces development time and simplifies the deployment of the model as an interactive application. This approach offers a practical and scalable solution for implementing intelligent monitoring systems in industrial settings.