Plastic Deformation of Metallic Foam

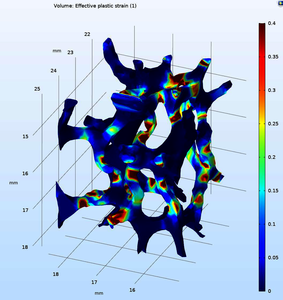

Metallic foams can be plastically deformed to dramatically alter the material’s mass density, microstructure, and bulk mechanical properties. This work investigates the plastic deformation of open-cell aluminum foams numerically, using high fidelity models of metallic foam constructed from micro-computed tomography scans and the elastoplastic material model interface in the COMSOL Multiphysics® simulation software. The use of boundary conditions such as applied pressure and applied displacement is discussed. The results of this analysis are compared to metallic foam samples that were plastically deformed in a hydrostatic pressure apparatus, which utilized pressures up to 1500 psi to uniformly deform a sample with a volumetric compression ratio of approximately 2. Simplified analytical expressions are presented that can be used to predict mass properties of the plastically deformed metallic foam samples.

下载

- cops_poster.pdf - 2.08MB