显示活动时间: 00:00 – 00:00

搜索

近期活动

正在加载活动内容

2026 年 3 月 5 日

| 14:00 HKT

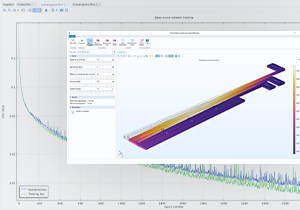

使用模型管理器进行仿真数据管理

COMSOL

网络研讨会

线上

2026 年 3 月 11 日

| 14:00 HKT

COMSOL 多物理场仿真简介(在线演示)

COMSOL

网络研讨会

线上

2026 年 3 月 12 日

| 14:00 HKT

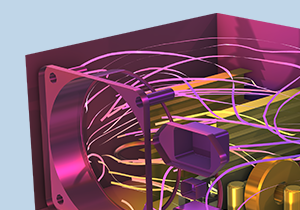

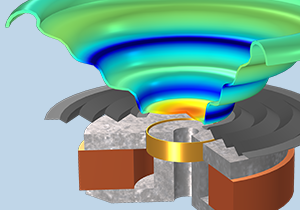

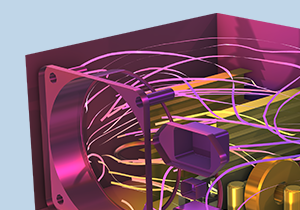

使用 COMSOL® 模拟高性能电机

COMSOL

网络研讨会

线上

2026 年 3 月 19 日

| 14:00 HKT

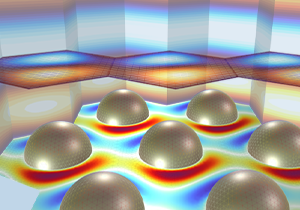

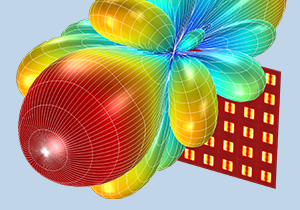

COMSOL® 多物理场仿真优化光学超材料设计

COMSOL

网络研讨会

线上

2026 年 3 月 26 日

| 14:00 HKT

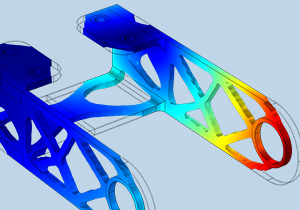

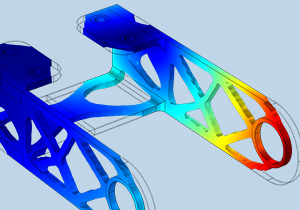

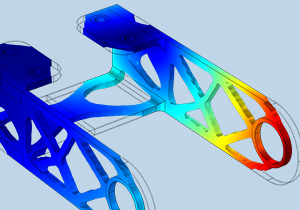

使用 COMSOL® 进行形状与拓扑优化

COMSOL

网络研讨会

线上

显示活动 5 场,活动总数 5 场。

| Date | Time | Title | Type | Host | Discipline |

|---|---|---|---|---|---|

| 2026 年 3 月 5 日 | 14:00 |

使用模型管理器进行仿真数据管理 |

网络研讨会 | COMSOL-线上 |

|

| 2026 年 3 月 11 日 | 14:00 |

COMSOL 多物理场仿真简介(在线演示) |

网络研讨会 | COMSOL-线上 |

|

| 2026 年 3 月 12 日 | 14:00 |

使用 COMSOL® 模拟高性能电机 |

网络研讨会 | COMSOL-线上 |

|

| 2026 年 3 月 19 日 | 14:00 |

COMSOL® 多物理场仿真优化光学超材料设计 |

网络研讨会 | COMSOL-线上 |

|

| 2026 年 3 月 26 日 | 14:00 |

使用 COMSOL® 进行形状与拓扑优化 |

网络研讨会 | COMSOL-线上 |

|

视频培训中心

网络研讨会视频点播

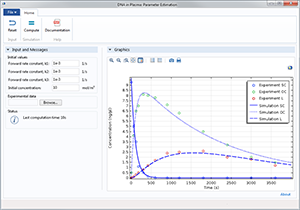

非线性结构材料参数估计

网络研讨会

Feb 05

COMSOL® 多物理场仿真在功率半导体中的应用

网络研讨会

Jan 29

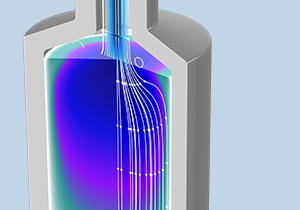

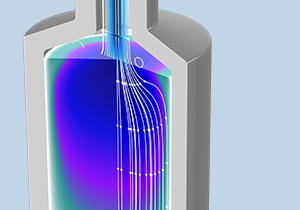

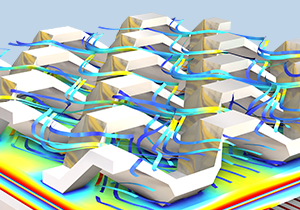

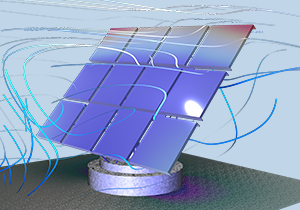

COMSOL® 中的流热耦合仿真

网络研讨会

Jan 15

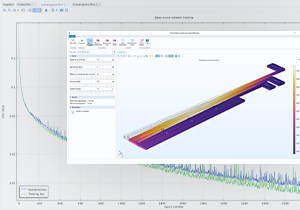

在 COMSOL® 中实现仿真流程自动化

网络研讨会

Jan 08

多物理场仿真结果的处理与可视化

网络研讨会

Dec 25

COMSOL Multiphysics® 6.4 版本功能简介

网络研讨会

Dec 18

COMSOL® 中的等离子体仿真

网络研讨会

Dec 11

COMSOL® 中的化学反应工程仿真

网络研讨会

Dec 04

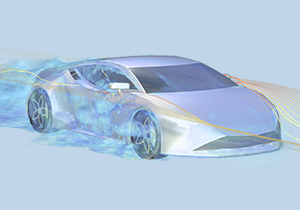

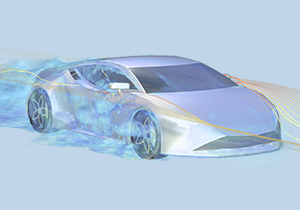

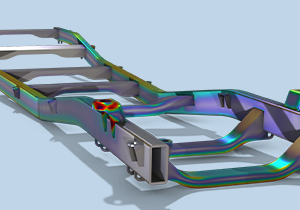

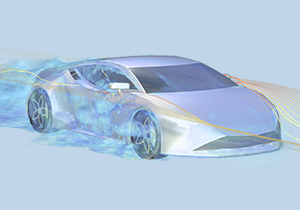

COMSOL® 多物理场仿真在新能源汽车领域中的应用

网络研讨会

Nov 27

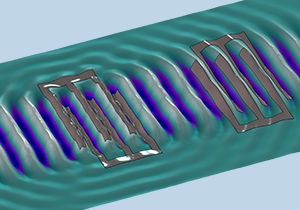

使用 COMSOL® 模拟声学超材料

网络研讨会

Nov 20

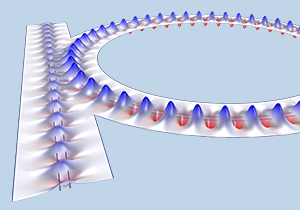

使用 COMSOL 模拟 RF 和光学周期性结构

网络研讨会

Nov 13

COMSOL 多物理场仿真在功率器件中的应用

网络研讨会

Oct 23

COMSOL 多物理场仿真在数字岩心中的应用

网络研讨会

Oct 16

在 COMSOL 中创建、训练和使用代理模型

网络研讨会

Sep 25

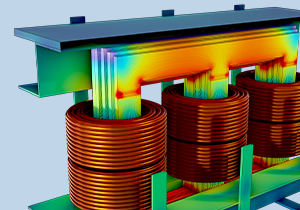

电力设备噪声的多物理场仿真

网络研讨会

Sep 18

COMSOL 多物理场仿真在声学中的应用

网络研讨会

Aug 27

COMSOL 仿真 App 开发、部署和应用

网络研讨会

Aug 21

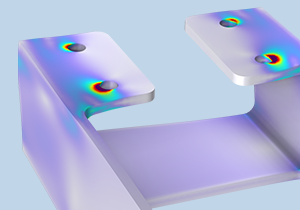

使用 COMSOL 模拟热应力

网络研讨会

Aug 14

COMSOL 在半导体封测中的应用

网络研讨会

Aug 07

使用 COMSOL 模拟多孔介质流和地下水流

网络研讨会

Jul 31

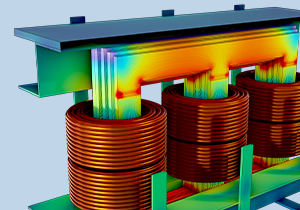

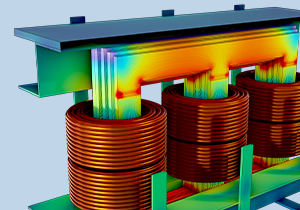

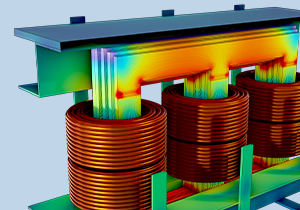

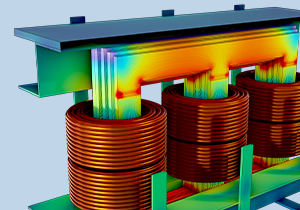

多物理场仿真在电力变压器中的应用

网络研讨会

Jul 24

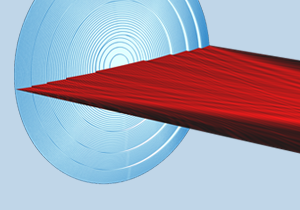

COMSOL 多物理场仿真在光学领域中的应用

网络研讨会

Jul 16

多物理场仿真在半导体制程中的应用

网络研讨会

Jul 10

COMSOL® 中的低频电磁场仿真

网络研讨会

Jul 03

使用 COMSOL 进行流固耦合仿真

网络研讨会

Jun 26

COMSOL® 中的传热仿真

网络研讨会

Jun 19

多物理场仿真在先进封装中的应用

网络研讨会

Jun 12

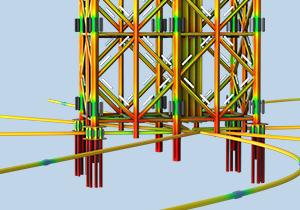

COMSOL® 在电力设备中的应用

网络研讨会

Jun 05

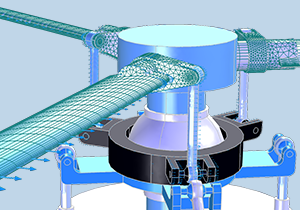

COMSOL® 网格划分功能介绍

网络研讨会

May 29

COMSOL® 在半导体薄膜沉积工艺中的应用

网络研讨会

May 20

COMSOL® 中的结构力学仿真

网络研讨会

May 15

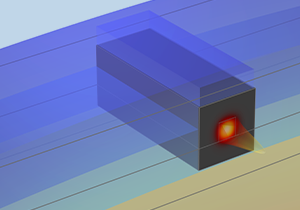

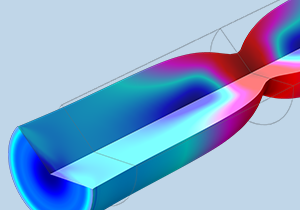

COMSOL® 中的 CFD 仿真

网络研讨会

May 08

将随频率变化的数据融入 COMSOL® 时域声学仿真

网络研讨会

Apr 24

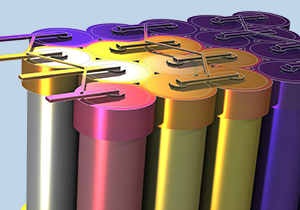

COMSOL® 中的电池仿真

网络研讨会

Apr 17

使用 COMSOL® 模拟生物传感器和检测设备

网络研讨会

Mar 27

使用 COMSOL® 模拟电声器件

网络研讨会

Mar 20

使用 COMSOL® 进行锂离子电池模型的参数估计

网络研讨会

Mar 06

使用 COMSOL® 模拟放电现象

网络研讨会

Feb 27

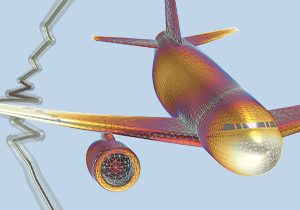

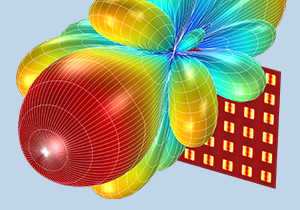

使用 COMSOL® 模拟雷达和天线

网络研讨会

Feb 20

使用模型管理器进行仿真数据管理

网络研讨会

Feb 13

LiveLink™ for MATLAB® 和 LiveLink™ for Simulink® 功能简介

网络研讨会

Jan 09

COMSOL® 中的低频电磁场仿真

网络研讨会

Jan 03

使用 COMSOL Multiphysics® 优化设计

网络研讨会

Dec 26

COMSOL® 中的结构力学仿真

网络研讨会

Dec 19

COMSOL® 中的传热仿真

网络研讨会

Dec 12

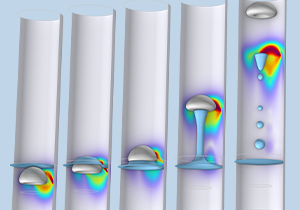

COMSOL® 中的多相流仿真

网络研讨会

Dec 05

COMSOL Multiphysics® 6.3 版本功能简介

网络研讨会

Nov 28

COMSOL® 中的转子动力学和多体动力学仿真

网络研讨会

Nov 21

COMSOL® 求解器介绍及设置方法

网络研讨会

Nov 14

使用 COMSOL Multiphysics® 模拟声学超材料

网络研讨会

Nov 07

多物理场仿真结果的处理与可视化

网络研讨会

Oct 24

COMSOL® 中的等离子体仿真

网络研讨会

Oct 17

COMSOL® 网格划分功能介绍

网络研讨会

Oct 10

电力变压器的多物理场仿真

网络研讨会

Sep 19

使用 COMSOL Multiphysics® 仿真高性能电机

网络研讨会

Sep 12

不确定性量化在多物理场仿真中的应用

网络研讨会

Sep 05

超声波及其应用的多物理场仿真

网络研讨会

Aug 29

使用 COMSOL Multiphysics® 模拟光电半导体

网络研讨会

Aug 15

COMSOL® 多物理场仿真加速数字岩心技术发展

网络研讨会

Aug 08

使用代理模型开发高效的 COMSOL® 仿真 App

网络研讨会

Aug 01

COMSOL® 多物理场仿真在地热能开发中的应用

网络研讨会

Jul 25

COMSOL® 仿真 App 开发、部署和应用

网络研讨会

Jul 18

COMSOL® 中的光学仿真

网络研讨会

Jul 11

非线性结构材料参数估计

网络研讨会

Jul 04

基于 COMSOL® 构建电力设备的数字孪生

网络研讨会

Jun 27

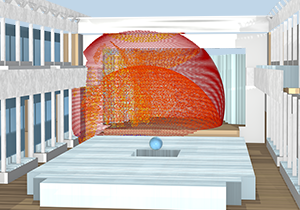

COMSOL® 室内声学仿真

网络研讨会

Jun 20

COMSOL Multiphysics® 在半导体制造中的应用

网络研讨会

Jun 13

COMSOL Multiphysics® 在绿氢技术中的应用

网络研讨会

Jun 06

使用 COMSOL Multiphysics® 模拟放电现象

网络研讨会

May 28

使用 COMSOL® 模拟 SAW/BAW 器件

网络研讨会

May 16

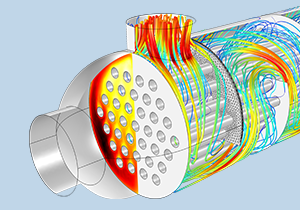

COMSOL® 中的换热器仿真

网络研讨会

May 09

COMSOL Multiphysics® 中的流固耦合仿真

网络研讨会

Apr 18

多尺度电磁波仿真

网络研讨会

Apr 11

COMSOL® 微执行器和微型电机仿真

网络研讨会

Apr 02

COMSOL® 中的湍流仿真

网络研讨会

Mar 26

COMSOL® 仿真在电力电子技术中的应用

网络研讨会

Mar 14

COMSOL® 中的流体动压轴承仿真

网络研讨会

Mar 12

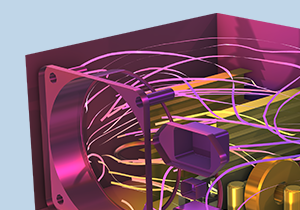

使用 COMSOL Multiphysics® 模拟 EMI/EMC 现象

网络研讨会

Mar 07

COMSOL® 中的热辐射仿真

网络研讨会

Mar 05

显示活动 6 场,活动总数 79 场。

| Date | Title | Type | Host | Discipline |

|---|---|---|---|---|

| Feb 05 |

非线性结构材料参数估计 |

网络研讨会 | COMSOL-线上 |

|

| Jan 29 |

COMSOL® 多物理场仿真在功率半导体中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Jan 15 |

COMSOL® 中的流热耦合仿真 |

网络研讨会 | COMSOL-线上 |

|

| Jan 08 |

在 COMSOL® 中实现仿真流程自动化 |

网络研讨会 | COMSOL-线上 |

|

| Dec 25 |

多物理场仿真结果的处理与可视化 |

网络研讨会 | COMSOL-线上 |

|

| Dec 18 |

COMSOL Multiphysics® 6.4 版本功能简介 |

网络研讨会 | COMSOL-线上 |

|

| Dec 11 |

COMSOL® 中的等离子体仿真 |

网络研讨会 | COMSOL-线上 |

|

| Dec 04 |

COMSOL® 中的化学反应工程仿真 |

网络研讨会 | COMSOL-线上 |

|

| Nov 27 |

COMSOL® 多物理场仿真在新能源汽车领域中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Nov 20 |

使用 COMSOL® 模拟声学超材料 |

网络研讨会 | COMSOL-线上 |

|

| Nov 13 |

使用 COMSOL 模拟 RF 和光学周期性结构 |

网络研讨会 | COMSOL-线上 |

|

| Oct 23 |

COMSOL 多物理场仿真在功率器件中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Oct 16 |

COMSOL 多物理场仿真在数字岩心中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Sep 25 |

在 COMSOL 中创建、训练和使用代理模型 |

网络研讨会 | COMSOL-线上 |

|

| Sep 18 |

电力设备噪声的多物理场仿真 |

网络研讨会 | COMSOL-线上 |

|

| Aug 27 |

COMSOL 多物理场仿真在声学中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Aug 21 |

COMSOL 仿真 App 开发、部署和应用 |

网络研讨会 | COMSOL-线上 |

|

| Aug 14 |

使用 COMSOL 模拟热应力 |

网络研讨会 | COMSOL-线上 |

|

| Aug 07 |

COMSOL 在半导体封测中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Jul 31 |

使用 COMSOL 模拟多孔介质流和地下水流 |

网络研讨会 | COMSOL-线上 |

|

| Jul 24 |

多物理场仿真在电力变压器中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Jul 16 |

COMSOL 多物理场仿真在光学领域中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Jul 10 |

多物理场仿真在半导体制程中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Jul 03 |

COMSOL® 中的低频电磁场仿真 |

网络研讨会 | COMSOL-线上 |

|

| Jun 26 |

使用 COMSOL 进行流固耦合仿真 |

网络研讨会 | COMSOL-线上 |

|

| Jun 19 |

COMSOL® 中的传热仿真 |

网络研讨会 | COMSOL-线上 |

|

| Jun 12 |

多物理场仿真在先进封装中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Jun 05 |

COMSOL® 在电力设备中的应用 |

网络研讨会 | COMSOL-线上 |

|

| May 29 |

COMSOL® 网格划分功能介绍 |

网络研讨会 | COMSOL-线上 |

|

| May 20 |

COMSOL® 在半导体薄膜沉积工艺中的应用 |

网络研讨会 | COMSOL-线上 |

|

| May 15 |

COMSOL® 中的结构力学仿真 |

网络研讨会 | COMSOL-线上 |

|

| May 08 |

COMSOL® 中的 CFD 仿真 |

网络研讨会 | COMSOL-线上 |

|

| Apr 24 |

将随频率变化的数据融入 COMSOL® 时域声学仿真 |

网络研讨会 | COMSOL-线上 |

|

| Apr 17 |

COMSOL® 中的电池仿真 |

网络研讨会 | COMSOL-线上 |

|

| Mar 27 |

使用 COMSOL® 模拟生物传感器和检测设备 |

网络研讨会 | COMSOL-线上 |

|

| Mar 20 |

使用 COMSOL® 模拟电声器件 |

网络研讨会 | COMSOL-线上 |

|

| Mar 06 |

使用 COMSOL® 进行锂离子电池模型的参数估计 |

网络研讨会 | COMSOL-线上 |

|

| Feb 27 |

使用 COMSOL® 模拟放电现象 |

网络研讨会 | COMSOL-线上 |

|

| Feb 20 |

使用 COMSOL® 模拟雷达和天线 |

网络研讨会 | COMSOL-线上 |

|

| Feb 13 |

使用模型管理器进行仿真数据管理 |

网络研讨会 | COMSOL-线上 |

|

| Jan 09 |

LiveLink™ for MATLAB® 和 LiveLink™ for Simulink® 功能简介 |

网络研讨会 | COMSOL-线上 |

|

| Jan 03 |

COMSOL® 中的低频电磁场仿真 |

网络研讨会 | COMSOL-线上 |

|

| Dec 26 |

使用 COMSOL Multiphysics® 优化设计 |

网络研讨会 | COMSOL-线上 |

|

| Dec 19 |

COMSOL® 中的结构力学仿真 |

网络研讨会 | COMSOL-线上 |

|

| Dec 12 |

COMSOL® 中的传热仿真 |

网络研讨会 | COMSOL-线上 |

|

| Dec 05 |

COMSOL® 中的多相流仿真 |

网络研讨会 | COMSOL-线上 |

|

| Nov 28 |

COMSOL Multiphysics® 6.3 版本功能简介 |

网络研讨会 | COMSOL-线上 |

|

| Nov 21 |

COMSOL® 中的转子动力学和多体动力学仿真 |

网络研讨会 | COMSOL-线上 |

|

| Nov 14 |

COMSOL® 求解器介绍及设置方法 |

网络研讨会 | COMSOL-线上 |

|

| Nov 07 |

使用 COMSOL Multiphysics® 模拟声学超材料 |

网络研讨会 | COMSOL-线上 |

|

| Oct 24 |

多物理场仿真结果的处理与可视化 |

网络研讨会 | COMSOL-线上 |

|

| Oct 17 |

COMSOL® 中的等离子体仿真 |

网络研讨会 | COMSOL-线上 |

|

| Oct 10 |

COMSOL® 网格划分功能介绍 |

网络研讨会 | COMSOL-线上 |

|

| Sep 19 |

电力变压器的多物理场仿真 |

网络研讨会 | COMSOL-线上 |

|

| Sep 12 |

使用 COMSOL Multiphysics® 仿真高性能电机 |

网络研讨会 | COMSOL-线上 |

|

| Sep 05 |

不确定性量化在多物理场仿真中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Aug 29 |

超声波及其应用的多物理场仿真 |

网络研讨会 | COMSOL-线上 |

|

| Aug 15 |

使用 COMSOL Multiphysics® 模拟光电半导体 |

网络研讨会 | COMSOL-线上 |

|

| Aug 08 |

COMSOL® 多物理场仿真加速数字岩心技术发展 |

网络研讨会 | COMSOL-线上 |

|

| Aug 01 |

使用代理模型开发高效的 COMSOL® 仿真 App |

网络研讨会 | COMSOL-线上 |

|

| Jul 25 |

COMSOL® 多物理场仿真在地热能开发中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Jul 18 |

COMSOL® 仿真 App 开发、部署和应用 |

网络研讨会 | COMSOL-线上 |

|

| Jul 11 |

COMSOL® 中的光学仿真 |

网络研讨会 | COMSOL-线上 |

|

| Jul 04 |

非线性结构材料参数估计 |

网络研讨会 | COMSOL-线上 |

|

| Jun 27 |

基于 COMSOL® 构建电力设备的数字孪生 |

网络研讨会 | COMSOL-线上 |

|

| Jun 20 |

COMSOL® 室内声学仿真 |

网络研讨会 | COMSOL-线上 |

|

| Jun 13 |

COMSOL Multiphysics® 在半导体制造中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Jun 06 |

COMSOL Multiphysics® 在绿氢技术中的应用 |

网络研讨会 | COMSOL-线上 |

|

| May 28 |

使用 COMSOL Multiphysics® 模拟放电现象 |

网络研讨会 | COMSOL-线上 |

|

| May 16 |

使用 COMSOL® 模拟 SAW/BAW 器件 |

网络研讨会 | COMSOL-线上 |

|

| May 09 |

COMSOL® 中的换热器仿真 |

网络研讨会 | COMSOL-线上 |

|

| Apr 18 |

COMSOL Multiphysics® 中的流固耦合仿真 |

网络研讨会 | COMSOL-线上 |

|

| Apr 11 |

多尺度电磁波仿真 |

网络研讨会 | COMSOL-线上 |

|

| Apr 02 |

COMSOL® 微执行器和微型电机仿真 |

网络研讨会 | COMSOL-线上 |

|

| Mar 26 |

COMSOL® 中的湍流仿真 |

网络研讨会 | COMSOL-线上 |

|

| Mar 14 |

COMSOL® 仿真在电力电子技术中的应用 |

网络研讨会 | COMSOL-线上 |

|

| Mar 12 |

COMSOL® 中的流体动压轴承仿真 |

网络研讨会 | COMSOL-线上 |

|

| Mar 07 |

使用 COMSOL Multiphysics® 模拟 EMI/EMC 现象 |

网络研讨会 | COMSOL-线上 |

|

| Mar 05 |

COMSOL® 中的热辐射仿真 |

网络研讨会 | COMSOL-线上 |

|

显示活动 79 场,活动总数 79 场。